DISPERSION HARDENING Meaning and

Definition

-

Dispersion hardening is a type of strengthening mechanism used in materials science and metallurgy to enhance the mechanical properties of metals and alloys. It involves the addition of small particles or phases, typically insoluble in the matrix material, to disperse within the metal matrix. The dispersion particles act as obstacles to the movement of dislocations, reducing the ability of dislocations to move through the material and leading to increased resistance to deformation.

The dispersion hardening process starts with the selection of the appropriate dispersion particles, which are typically solid and have a different crystal structure or composition from the matrix material. These particles are then added to the metal matrix through techniques such as powder metallurgy, alloying, or mechanical alloying. The dispersion particles are uniformly distributed within the metal matrix, forming a secondary reinforcing phase.

The dispersion particles hinder the motion of dislocations by acting as barriers to their movement. When stress is applied to the material, dislocations tend to pile up around the dispersion particles, causing strain localization and preventing the dislocations from propagating further. This results in improved strength, hardness, and wear resistance of the material.

The effectiveness of dispersion hardening depends on factors such as the size, morphology, and distribution of the dispersion particles within the matrix. The properties of the dispersion particles themselves, including their volume fraction and compatibility with the matrix material, also play a significant role in determining the final mechanical properties of the material.

Common Misspellings for DISPERSION HARDENING

- sispersion hardening

- xispersion hardening

- cispersion hardening

- fispersion hardening

- rispersion hardening

- eispersion hardening

- duspersion hardening

- djspersion hardening

- dkspersion hardening

- dospersion hardening

- d9spersion hardening

- d8spersion hardening

- diapersion hardening

- dizpersion hardening

- dixpersion hardening

- didpersion hardening

- diepersion hardening

- diwpersion hardening

- disoersion hardening

- dislersion hardening

Etymology of DISPERSION HARDENING

The etymology of the word "dispersion hardening" can be broken down as follows:

1. Dispersion: This term derives from Latin "dis-" meaning "apart" or "asunder" and "spargere" meaning "to scatter" or "spread". Hence, dispersion refers to something being scattered or spread apart in different directions.

2. Hardening: This word comes from the Old English "heard" which means "hard" or "difficult". Hardening refers to the process of making something harder or stronger, typically through a treatment such as heating and cooling.

Therefore, "dispersion hardening" refers to a specific technique of strengthening a material by distributing tiny particles or phases throughout to improve its mechanical properties and make it more resistant to wear, deformation, or fracture.

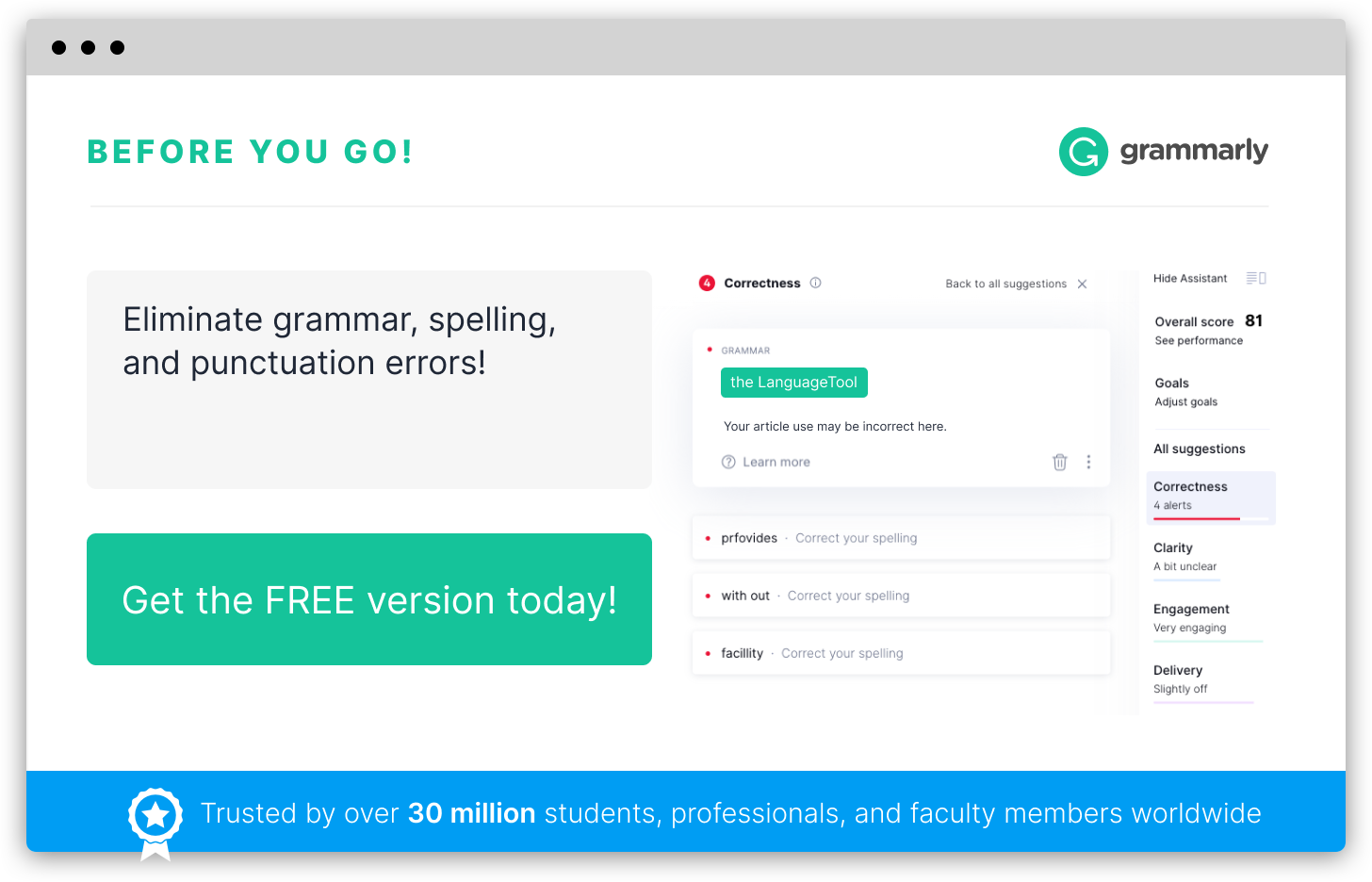

Infographic

Add the infographic to your website: